The beginning of a constant growth

COMPANY

HIGH PERFORMANCE FORGING

![]() Valvital S.p.A., machining; hot forging workshops, is working since 1971. The founders are Cavalier Gino Pellegrini (knighted in Italy for his work achievements) and his son Pier Giorgio Pellegrini, President and CEO. The company operates in the field of forging and mechanical processing. Valvital S.p.A covers an area of 32,000 sq.m, especially 9356 are indoors. While at first the company specialized in the production of valves for marine engines, at the present time its production has turned to large companies manufacturing tractors, trucks, forklifts, transmissions and gear boxes. After a few years, thanks to the machinery at their disposal and because of an insufficient development of the market in which it operated, the company’s founders decided to move production to what became their today’s field: 1974 brought the introduction of hot forging of transmission shafts, pinions and mechanical production of the axle shafts for tractors and industrial vehicles. Given the favourable performance of the market, the company has expanded on the European and world markets, reaching 93% of the current total turnover value.

Valvital S.p.A., machining; hot forging workshops, is working since 1971. The founders are Cavalier Gino Pellegrini (knighted in Italy for his work achievements) and his son Pier Giorgio Pellegrini, President and CEO. The company operates in the field of forging and mechanical processing. Valvital S.p.A covers an area of 32,000 sq.m, especially 9356 are indoors. While at first the company specialized in the production of valves for marine engines, at the present time its production has turned to large companies manufacturing tractors, trucks, forklifts, transmissions and gear boxes. After a few years, thanks to the machinery at their disposal and because of an insufficient development of the market in which it operated, the company’s founders decided to move production to what became their today’s field: 1974 brought the introduction of hot forging of transmission shafts, pinions and mechanical production of the axle shafts for tractors and industrial vehicles. Given the favourable performance of the market, the company has expanded on the European and world markets, reaching 93% of the current total turnover value.

Valvital S.p.A.’s production covers the following areas:

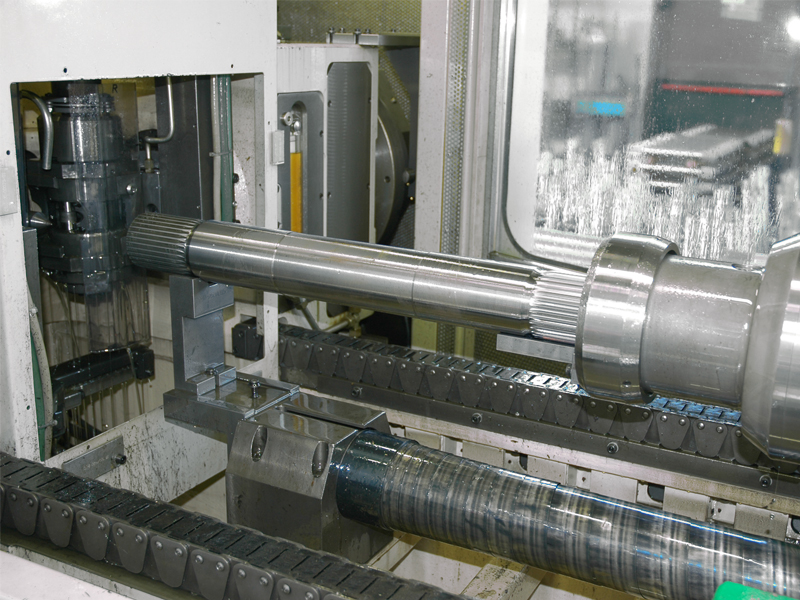

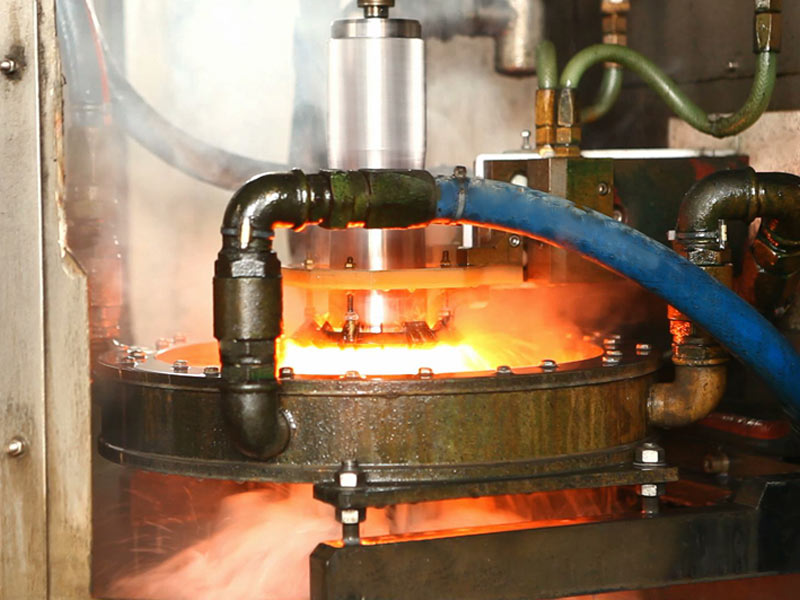

FORGED ROUGH MATERIALS: transmission input shafts, axle shafts for tractors, transmission shafts, pinions, double upset shafts, differential shafts. PROCESSED GOODS: transmission input shafts, axle shafts for tractors, pinions, brake shafts, shafts in general.our history

- 1971 Foundation of Valvital S.p.A. by Cav. Gino Pellegrini and his son Pier Giorgio.

- 1974 Installation of “AJAX 4” and “6 AJAX” forging machines.

- 1978 Installation of “NATIONAL 5” forging machines and opening to the European markets.

- 1995 Introduction of the first semi-automatic line: VACCARI PV 330 screw-press and hydraulic press.

- 1998 Expansion of the mechanical workshop department through the integration of a new park of CNC machines.

- 2007 Construction of the new forging department and installation of the first fully robotic AMP 460 line.

- 2012 Commissioning of the second completely robotic line AMP 360.

- 2020 Commissioning of the third completely robotic line LASCO SPR3150.

Ethics code of conduct

Valvital S.p.A. has decided to identify, as an expression of the autonomous form of adherence to the values of ethics and honesty in the management of its business, further principles of conduct which are included in this Ethics Code. (View)

Environmental policy

Valvital S.p.A. is committed to implementing policies and actions to safeguard the ecosystem, through a responsible environmental resources and raw materials consumption.

Quality policy

Effective improvement requires the involvement and participation of everybody. The Management and all the Managers therefore guarantee a constant personal obligation to support the improvement plan and monitor its performance.

ORGANIZATION AND MANAGEMENT ACCORDING TO LEGISLATIVE DECREE NO. 231

Model 231, prepared by Valvital S.p.A, is based on a structured system of organizational, operational and monitoring procedures: identify the areas/processes of the possible risks in business activities and establish a system able to plan the formation and implementation of Company decisions.

(View)

Copyright © 2014 – Valvital S.p.A. – All rights reserved

P.I. & C.F. 00527810014 Valvital SpA – Iscritta al registro delle imprese di Torino con n°iscrizione 449710

Capitale sociale effettivamente versato risultante dall’ultimo bilancio € 2.080.000,00

Designed and hosted by Aries S.r.l.